Click Here if you listened. We’re trying to gauge interest so only one question is required; however, there is a spot for feedback!

Read along below!

Keeping Beeyards on Trailers

Keeping Beeyards on Trailers

“Mobile Beeyards”

By: James E. Tew

Figure 1. Jeff Ott, Beekeeper, Podcaster and conversationalist.

Trailering Bees

I recently chatted with Jeff Ott, an experienced beekeeper about trailering bees (Edited comments taken from “Bee Trailers – The Portable Bee Hive” podcast, Honey Bee Obscura, May 18, 2023. Podcast #126. https://www.honeybeeobscura.com/bee-trailers-the-portable-bee-hive-126/). I recorded the conversation and transcribed it for you.

Jim: I must have five trailers right now, and before anybody says, “Oh, my stars!” you should know that they’re all small. I’ve got anywhere from really small trailers that go behind my small tractors all the way up to two bigger trailers that I can tow behind my truck.

At one time or another I have had bee colonies on every one of those trailers. It’s been my experience, as an older beekeeper, that I want wheels or rollers on everything in my bee life.

When moving hives for pollination, even as a younger man, I was eager to use trailers. Is there any way that I can use a trailer and not have to take these colonies off this truck, set them down, go back eight to 10 days later, and do the whole thing over again? It’s a vast amount of work to load and unload hives.

An immediate question for the grower is, “Can I just put these hives on a trailer and then unhook it and be gone?” Many times, the growers would stand their ground and require me to set colonies throughout the orchard. That was a lot more work and it is easier to lose a colony in tall grass.

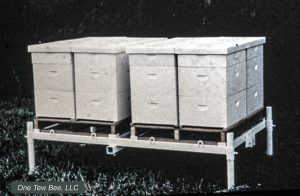

Figure 2. A commercial beekeepers’ trailered hives for pollinating cucumbers.

Jeff: The big guys, have their front-end loaders and pallets and they’re all set to do this kind of in-and-out type of beekeeping and pollination or whatever you’re doing. All the while, moving from one location to another while following the bloom, so to speak. Smaller beekeeping operations can’t afford the front-end loaders or skid loaders, and the trailer becomes a viable option. There’s a lot to consider when you’re looking at a trailer for hauling bees.

Jim: Right off the bat. You almost said it, I was waiting for it – right off the bat, “Why would I use a trailer of any size?” My immediate response is because they are generally much lower to the ground than my pickup or a larger truck. I don’t have to pick the colony up or lift the colony as high off the ground.

Yes, I can use ramps on the tailgate of the truck, but do you want someone to make pictures of you when you’re trying to pull that beehive up those ramps – backwards – into the truck? That foot and a half or so height difference really matters. If you got the right trailer, it may actually have loading ramps that are built on the back of it.

Jeff: Yes.

Jim: I find it much easier to load a trailer with bees than I do to get them up in my truck or, in the old days, on a flatbed truck, and then get them back off.

Figure 3. A hybrid-looking system using a front-end loader to set hives from the truck onto a farm wagon for distribution around the planting.

Jeff: No, it only takes once or twice of trying to load a heavy beehive into a back of a pickup truck before you realize this won’t work as a regular event. It’s good for once or twice when moving a beeyard. If you’re doing on a regular basis, the trailer really comes in handy and the lower to the ground – within limits – the better.

You have to take into consideration where your beeyards are located. If you’re doing pollination contracts or following the bloom, then you have to consider ground clearances. That becomes a whole different factor in trying to decide what trailer you want.

Jim: If you’re going to unhitch the trailer and then back it up again, yes, the beekeeper wants to know if the yard is level. Is the yard solid? In a perfect bee world, the sky is always blue, birds are always singing, and bees are always happy, but the common reality is that it’s 2:30 in the morning, the dew has fallen, the truck’s slipping on the grass, and you can’t see the hitch. You’ve got no one to help you because you’ve got no friends, Jeff. You’ve already been through all of them years ago. The devil is in the details.

Jeff: The only friends you have at that time is mosquitoes. They’re all over you.

Jim: [laughs] They’re not friends. They’re just there at the same time. I do want to put this in our discussion right now. If you haven’t done it, you are probably going to do it.

Here’s the situation. If you’ve got a smallish, single axle trailer, you listened to a podcast or you read an article somewhere, and you bought a trailer. Now it’s time to return and hitch it back to the truck. When that trailer is not hitched to the truck and the hives are not situated right over the axle, or even better, nearer the front of the trailer, the tongue will fly up in the air because you suddenly put your body weight on the back of the trailer. The axle, serving as a fulcrum, with the hives in the center, will tilt up. Suddenly, you’ve abruptly got your bees unloaded. They’ll come sliding down that trailer towards you. So, hitch the trailer to the truck first. Then work with the colonies. All those years ago, that brings me to the very next point, if possible, that the towing vehicle should be a four-wheel drive vehicle.

Jeff: Your towing vehicle?

Jim: Yes, your towing vehicle should be four-wheel drive. Like I said, the world’s not always perfect. Sometimes it’s rainy and muddy. You’ve mentioned pollination work. In fact, I’ve moved hives most of the time not for pollination work, but for management reasons.

For instance, I had a couple of hives that wouldn’t stop stinging the whole neighborhood. The move was not a huge one. This was just a move of two colonies. I’m really going to have trouble finding someone to help me move them. I still used the trailer because I’ve got bees that are stinging everyone in sight requiring me to work alone.

So, I still used the trailer – massive overkill – just removing those two genetically angry colonies to a location 40 miles away. The funny part of this story is that a bear found those two colonies. Eastern Ohio beekeepers had not had a bear-sighting in about 100 years. I almost got my name in the local newspaper. The bear destroyed those two colonies. I wrote about this in an earlier article.

Now, you’ve got a four-wheel drive truck and just a single axle trailer, maybe 12 to 14 feet long, and you’re going to take it to a beeyard. That yard must be able to take that kind of rig turning around, backing up, getting out. A lot of beeyards will not work well for trailering your bees just because you’re going to have to do some sophisticated driving and backing if the yard is too small.

Jeff: It needs to be able to handle it with a loaded trailer. A lot of times an unloaded trailer sits differently than a loaded trailer. You can get in there but you can’t get out or you get it loaded up, but you can’t get backed up. You need to put these characteristics in consideration.

When I had horses, I always used a gooseneck trailer. I love gooseneck trailers. Regarding trailers for bees, do you prefer a gooseneck trailer or a bumper hitch? Secondly, how many axles should the trailer have? One or two? Two axles is a lot more stable and you don’t have that fly-up of the hitch that you have a concern with a single axle. What’s your experience on that?

Jim: I have some guesses, some opinions, and some experience.

Jeff: Sure.

Figure 4. A heavy duty trailer with brakes and a pentel hitch on two axles.

Jim: The two-axle trailer is probably going to have brakes on it, so that really helps. Even a loaded single axle trailer, medium size, 16 feet long with 15, 20, 30 colonies of bees on it, it’s going to really push the truck. You, the driver, must realize that the stopping distance is going to be greatly increased to stop the truck. Double-axle trailers usually have brakes – surge brakes on the tongue – or something like that.

Secondly, those larger trailers are also heavier making it a different concept. More pressure on you the driver and more gas consumption. They are more stable, but there’s a limit on what weight you can put on the bumper hitch.

I pulled a trailer, loaded with good junk, all the way from South Alabama to Northeast Ohio. I didn’t notice until I was backing down my home driveway that my bumper had twisted downward on the truck making my bumper position at about a 35-degree angle. The bolts that held the bumper to the truck frame had slipped.

I was home, but I still had a fearful moment there. What if the bumper had come off? It’s a bumper hitch, so the trailer could have come loose from the truck.

Now, having gotten to this point, I have not routinely used a gooseneck. I’m going to have to depend on you. We’ve used horse trailers and made them work for moving the equipment primarily, but I never used a gooseneck trailer of any kind for moving hives. It was always a bumper hitch or a heavy-duty pentel hitch. You tell me what was involved when hooking up that gooseneck to the truck. You said it was more stable, easier to back. How difficult was it to attach a gooseneck trailer to the truck?

Jeff: It’s a much more stable ride in the wind. That trailer attached as a gooseneck is a much more secure trailer. Backing was a lot easier. It’s more natural, more intuitive, when backing. Even lining up the hitch and hooking it up was easier because, in most cases, you could see it up to the final second to the hitch the trailer in the middle of the truck bed. I understand some of the new trucks now even have a camera looking at the center of the bed of the truck. Even lining it up with a camera is just like many cars now with a backup assist. The downside is that these trailers are more expensive.

Jim: Jeff, I’ve got a question that I guess I’ll check out after we finish this conversation, but right now, can you tell me, what’s the different between a trailer and a wagon?

Jeff: When you say wagon, the only thing I can think of is it says Radio Flyer stamped on the side, or it’s being towed behind a tractor loaded full of hay.

Figure 5. Pollination hives on a hay wagon. This was not a suitable trailer for the open road.

Jim: That’s exactly where I was going. Years ago, I thought I had a bright idea. I took some of the university hay wagons – they’re just very utilitarian devices – and put pollination hives on them. I nailed the pallets and the bottom boards to the deck of the trailer and then put the colony components on the nailed bottom boards. It really made a secure ride. These hives are staying on that trailer. All I had to do was keep the outer covers on.

What’s fundamentally wrong with this? Answer? By the time I got where I was going, I had a load of the angriest, most upset bees you’ve ever seen, and I realized on the trip that you can only go about 20 miles per hour. A hay wagon has no suspension system on it. It’s a slow wagon with a rough ride.

I’m hypothesizing that the difference between a trailer and a wagon is the suspension system, or the lack of it. If anybody has any interest in using a hay wagon, you’re going to have to go at 15-20 miles per hour. If you go much faster, you’re going to be bouncing bees all over the community because there’s not enough weight to settle the trailer out – even if you run the tire’s half slack. That hay wagon idea blew up on me. I was not able to use those simple farm wagons as a bee-moving device on the highway. They work fine within the orchard.

Jeff: Interesting.

Jim: When you mentioned the horse wagon a bit ago, the horse trailer, you wandered into a different arena. Those are enclosed trailers. Cargo doors close them up. I had a shock years ago using a cargo truck (not a trailer) with fold-down doors. I want to tell you it’s really easy, even when the temperature outside was in the 20’s, to overheat that load of bees in an enclosed container.

You’re bouncing them, you’re jostling them, they’re upset, they’re confined. They’ll begin to get worked up and generate heat. It was shocking to have those colonies overheat when the outside temperature was so cold. Now, as I said, that was not a trailer, but an enclosed box truck. Though it’d be the same situation with an enclosed trailer.

My situation was laughable. I had to stop at one of those all-night food stores and buy all the ice they had. While it was frigid outside, I had to put ice on those colonies to calm them down. If you use an enclosed trailer, even on a cold day, you can still overheat the colonies and suffocate them because of the jostling effect that they’re going through with all of that.

Jeff: Not to go off on this tangent but that story reminds me of the time I was in Georgia, and I did a couple of articles on Wilbanks Apiaries. I was doing an article for Bee Culture, and I was talking to the owner. He showed me around his queen-rearing facility. Of course, he does a lot of packages and he had specially designed trailers for moving packages of bees. They were temperature controlled. He can control the temperature inside that enclosed trailer for his bees, which was an interesting concept, but addresses the concern or issues that you faced.

Jim: The reason I’m on this tangent is because of the same thing. A fellow beekeeper here, who contract-hauls packages every Spring, has an environmentally controlled trailer with doors, fans, vents and thermocouples, because he basically says the load is critical. You can insure the trailer, and you can insure the truck, and carry medical insurance – but you can’t insure the live bees. If you overheat those bee packages, that’s a disaster. In his enclosed trailer he’s towing, he knows exactly what’s happening, temperature-wise, from the cab of his truck.

Jeff: That’s smart. Speaking of enclosed trailers, one of the things that I think you’ve seen, and all beekeepers have seen these days, some people and especially in Europe, they are using trailers and AZ-type hives to move bees around.

Jim: Isn’t that interesting. I’ve only seen pictures of that.

Jeff: I look at that and what I know of AZ hives, I think, boy, that would be really a great way of doing things. I still to this day like the idea of putting beehives on a trailer to make my life easier as a beekeeper, a better beekeeper, and the AZ hives could be a good way to go. Putting all of that into a trailer would be fantastic.

Figure 6. A custom trailer, with a detachable deck, designed to haul eight hives.

Jim: I want to go a little bit deeper down this rabbit hole that you’ve started. [laughter] About sixty years ago, a USDA researcher designed a trailer that allowed the platform bed to be jacked up and taken off the mobile trailer frame. You put four legs down on each corner of the platform, jack the platform up, and raised the platform, with the hives, off the mobile frame of the trailer. Then pull that frame out from under the platform and off you go. You took this strange looking, partial trailer-frame behind you leaving the platform and the hives at the cucumber field.

Jeff: That’s like the container trailers that we see in the Pacific Northwest all the time. I’m sure they’re everywhere. You see those without the container on them. It’s just a frame with wheels.

Jim: Yes.

Jeff: I like that idea.

Figure 7. Platform unloaded from the trailer frame.

Jim: Let me tell you where it went. Let me tell you [laughter] why the researcher said you don’t see such bee trailers. When you’re going back to get your platform and its night and the truck’s slipping, everything must be lined up exactly straight. If the mobile frame strikes either one of those back legs, the platform dumps the colonies off the bed.

Jeff: Oh my gosh!

Jim: This very event happened and about 40 colonies either shifted or fell from the trailer deck. He had some pictures of that 40-colony load of bees on that platform, tilted to one side where he accidentally struck one of the back legs. He decided the risk was too great. The idea died.

Now there’s a Chapter Two to this saga. Years ago, I gave this same description to a beekeeping audience. To me, the audience is all beekeepers, but in reality, they’re candlestick makers, soldiers, and sometimes even airline pilots. My point is that they are a blend of people with a myriad of talents. I didn’t know I was talking to two professional welders. From my lecture description, they made that very trailer design, but on a much smaller scale. They took the rear wheel hubs from an ancient Oldsmobile Toronado. That was one of the first front-wheel drive cars.

You would lower pipe legs on the corners of the trailer bed and raise the deck off the frame. There’s ways to do that, but I won’t go into it. Then, with the deck picked up, the wheels are off the ground. You pull out a pin, pull the wheel hubs off, put those in the back of the truck. The tongue was also detachable. You put that in the truck, too. Then in theory, you took the two wheels and the tongue back to the home apiary where you had what? Other platforms. Then you hauled eight different colonies somewhere else. This design was for a small bee operation. That’s why I told you a bit ago that I thought the difference between a trailer and a wagon was suspension.

The idea didn’t go anywhere. Not because you knocked out the back legs, but because the ride was so rough that we’re now back to 15 miles an hour again without a suspension system on the trailer. You just about can’t use it to move bees because it’s so rough on the colonies. This idea, this beautiful, professionally made piece of equipment – one of a kind – never developed. It was just another idea for people exploring what beekeepers could do with trailers to keep from having to unload and reload bee hives.

Jeff: Considering the amount of brain power that’s been put into that over the years by various beekeepers, I’m surprised there’s no easy, readily made solution these days.

Jim: I want to finish on this note. If you have a big truck towing a large trailer and you’re on a narrow country road getting to a beeyard, you better be crystal clear that that truck will make the turn through the gate that you’ve got to go through to get to where you’re going to drop those hives. Because one night, long ago, there was no way – the geometry was all wrong – that I could get my big truck to turn with that long trailer behind it to get through a narrow farmgate.

We had to unhitch the trailer in the road, unload the truck in the out-yard, bring the empty truck back, take the hives off the trailer, load them on the truck, then take the truck to the drop-off site and unload it again. A lot of good it did to have a trailer behind the truck that night. [laughter]

I love trailers. If you don’t have a trailer behind you when you’re moving bees, you’re just not doing your job correctly. Of course, I am kidding. There are quirks to trailering. All trailers have them.

Jeff: I think it comes down to understanding your use of that trailer and your beeyards. Not only can you use that trailer in your beeyard or your multiple beeyards in nice sunny weather, but can you use that trailer in that beeyard on the worst possible days in the dark?

Jim: And do it all by yourself?

Jeff: Yes, by yourself. It’s just that not every yard is on a flat surface. It’s not always going to be on a flat asphalt surface. It’s going to be on an angle, it’s going to be wet, it’s going to be in the mud and the bees are not going to be happy. We haven’t even talked about how do you secure the beehives to the trailer?

Jim: That is a totally different subject. Ratchet straps, hammers, staples. Do not think that the propolis seal will hold that equipment together. Don’t think that the colony will stay together because it’s stuck together with propolis. I have tried that. You’ve got to strap them, but now we’re off the subject. I like trailers, I want to use them for everything. If you use them, they’re going to come with some quirks and caveats, but overall, they give you a broader aspect of beekeeping.

Jeff, I enjoyed chatting with you. Thanks for educating me.

Dr. James E. Tew

Dr. James E. Tew

Emeritus Faculty, Entomology

The Ohio State University

tewbee2@gmail.com

Co-Host, Honey Bee

Obscura Podcast

www.honeybeeobscura.com