By: Ray Nabors

Honey Plants, Honey, And A Bit About Using Nucs.

The privilege of writing for the readers of Bee Culture has recently been granted to this writer. I have written for Bee Culture in the past but that was many years ago. It seems to me writing is best started at the beginning and we shall start way back. A friend of mine, an entomologist of note, was once asked, “when did you become interested in the study of insects”? His reply “at about age six.” You might be amazed at how many people with doctoral degrees showed interest in their chosen subject early in life.

At the age of six, I resided out in the county. A land owner had sold a small parcel of property to a developer. Modest houses were lined up and down a few streets. In the one where I resided there was a large Hibiscus syricus (popularly called Rose of Sharon) in the side yard property line. I was fascinated with the honey bees gathering nectar and pollen from that profusely flowering shrub. I learned how to catch a bee in the flower, grab her by the wings at her back, let her sting my leather belt and then I could play with the bee for a long time. Unfortunately, I realized the bee always died within an hour after her stinger was removed. So, my tactics changed.

I began to use a mason jar with lid to capture the bees, flower and all. It was possible to watch the bees and they did not die so quickly. When I let them go, they all flew in the same direction. Soon I realized if they all went in the same direction they must be going somewhere, which might be their home. Then I learned to turn loose one at a time and follow that bee as far as possible then let loose another (Dr. Seeley explains this very well). Many of the largest trees had been left from the old farmstead. They were used to shade the houses. Within the next block of houses a short distance one such tree had a colony of bees near the middle in the hollow void left by heart-rot. I could climb the tree, set on a large lower limb and watch the bees coming and going. That activity provided summer time entertainment for several years.

Eventually my bee studies come to end. As I went through the early change of life, my biological interest turned to the females of my own species. Later, when my time came, I went into military service.

When I left the service, it was back to college. By that time, I had a wife and children. I studied Agricultural Biology in graduate school and did some research with honey bees. My graduate research in honey bees fueled my interest with several of my own beehives as well as the University’s beehives. I have been looking into bees for a long time now.

Many beekeepers today are aging. Some have trouble handling the weight of a fully loaded standard super. Eight frame equipment has become more popular recently. A friend and fellow beekeeper, Steve Cooper, moved to the Missouri Ozarks from California. He is one of many Californians that have found the Ozark plateau both beautiful and economical. He worked for many years with Steve Taber. They raised queens for sale in nucleus colonies. He makes nucleus colonies for sale now in Missouri. He keeps all his bees in Nucleus size hives. I am fascinated with the technique. So, I must find out if this is a good way to make comb honey.

This is not the only hive style I wish to experiment with, but the other long hive idea has been put on hold until the nucleus hive is tested for honey production. The basic idea is to keep a productive colony in a nucleus hive three stories high. That is a total of 15 frames. It is enough for a hive of bees. It is also more like a hive in a hollow tree where bees rarely build more than five adjacent combs for their residence. It is, more natural for the bees and the boxes are light enough for anyone. More women and younger people are becoming interested in bees now. It is not only older beekeepers that can use these hives but probably most beekeepers that are not migratory will appreciate the convenience.

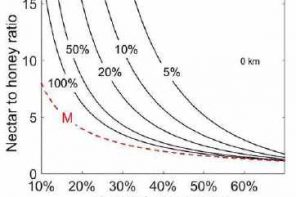

There is one thing that has not been tested with a nucleus hive. Can they be used for making honey? If bees can be increased and sold, then I suspect honey can be made. However, will these colonies make comb honey? That is the question we will attempt to answer this season. Comb honey is a specialty product. It sells for special prices. The honey in this area is some of the best in our nation. Most of my comb honey is made from Hibiscus (Gossypium hirsutum) and legume (Glycine max). Everyone that is familiar with floral sources knows that enough hibiscus makes a fine yellow honey.

Everyone does not know that cotton is a hibiscus with large white flowers and a red center to attract honey bees. The plant also has extrafloral nectaries on the petioles and green stems. Legume honey is prized every where in the world. Legumes include clovers, vetch, alfalfa, all types of beans and many trees are legumes. We have a million acres or more of soybeans here. Apiaries here are about a mile to a mile and a half apart. We have several commercial beekeepers. This is the Delta of the largest river in North America. My honey is made where the states of Kentucky, Missouri and Tennessee come together. Kansas is always accused of being flat. This is the northern apex of the Mississippi River Delta. Our elevation is about 250 feet above sea level. It is 500 miles to the Gulf of Mexico. The River and Delta drops six inches per mile. That is flat.

- Cotton.

- Soybean field.

The comb honey from this area comes out a light-yellow color. Pure legume honey tends toward water white. It is the cotton that gives the color. The honey flow here is primarily made on these two plants. The weeds here are so numerous in variety that we have one or more species of every weed family in North America growing in the ditches built to drain this swamp.

M ost of the nucleus boxes for sale today were never intended to become hives for bees. Steve Cooper makes his own out of stock lumber. Making bee equipment out of stock lumber is usually wasteful. You cannot buy a 1” x 10” board and make a bee hive. The board is about 9.3 inches wide. A standard frame will not fit that depth, it is too tall. A 1” x 12” board must be ripped down to make the sides. My solution is different than Steve’s. He makes his boxes from scratch. If you shop, you can find economy or commercial standard hive body boxes for about a dollar more than the 1” x 12” lumber will cost at the lumber shed.

ost of the nucleus boxes for sale today were never intended to become hives for bees. Steve Cooper makes his own out of stock lumber. Making bee equipment out of stock lumber is usually wasteful. You cannot buy a 1” x 10” board and make a bee hive. The board is about 9.3 inches wide. A standard frame will not fit that depth, it is too tall. A 1” x 12” board must be ripped down to make the sides. My solution is different than Steve’s. He makes his boxes from scratch. If you shop, you can find economy or commercial standard hive body boxes for about a dollar more than the 1” x 12” lumber will cost at the lumber shed.

My solution is to buy the standard hive bodies, cut a 1” x 12” board to a length of 197/8” and use that for one side of the hive box. The standard hive body box is cut in two pieces to make the other three sides. It already has frame rests on the end. This is how we can make five-frame equipment using standard stock bee equipment. It is faster than building them from scratch. It is surprising to me that beekeeping supply houses do not make a five-frame hive body. Plastic and paper nucleus boxes are not adequate for long term outdoor use.

The tops and bottoms for five-frame equipment is easily constructed from 1” x 10” stock lumber. A standard 1” x 10” board 8’ long can be cut into four pieces 2’ long making four tops or four bottoms as needed. Whenever I cut or rip a board, there is a technique I use to reduce warping. Even with bee equipment ordered from suppliers, I also use this technique. All you need is a high-grade water proof glue. Spread this glue on all the rough-cut edges. Water absorption will be restricted, and warping will be reduced. Using standard 1” x 2” stock for framing the bottom boards works fine. This lumber is ¾” thick and 1.5” wide. If you wish to make it more precise, simply rip it down so the thickness is reduced to ½”. That will be about perfect for lifting the hive body off the bottom board. When you rip down 1” x 12” boards. the left-over pieces can be used to make cleats (or handles) for the ends of your new five-frame boxes. Cutting 1’ x 2’ boards down to 19¾” also leaves behind pieces that make good cleats. The routed hand hold in standard boxes are not present on all sides of a home fashioned five-frame hive body or super. Attaching cleats with glue and deck screws is the answer.

Shallow supers can always be fashioned in the same way as the standard hive bodies. A standard 1” x 12” board can be ripped into equal halves and will make two shallow super sides without much waste. Some shallow super boxes are a bit taller than others by an eighth inch. I center these so there is 1/16” off top and bottom. The bees will fix that little gap in no time. It will also provide ventilation. Currently, we (my bees and I) are in the process of changing from 10-frame equipment to five frames. Dr. Jim Tew, in a recent article gave some information about advantages of five-frame equipment. The interest is growing. We may see five-frame equipment available commercially soon.

Bee Good, raymond.a.nabors@gmail.com.