By: Kim Flottum

Buzz Riopelle is the first beekeeper I got to know when I moved to Medina for my job here. The Medina County Beekeepers Association met in the Root Company’s office lunch room at the time since there were only about a dozen or so members and three or four were Root Company employees. It was one of those employees, Walter Thomas, who invited me to the meeting, held on a Sunday afternoon.

When it was time for the April meeting, I walked in and looked around. There was one fellow there who looked to be about my age – 40 something. Everybody else was older – much older it seemed. A couple of wives were there as I recall, but is was mostly a gathering of old men.

When it was time for the April meeting, I walked in and looked around. There was one fellow there who looked to be about my age – 40 something. Everybody else was older – much older it seemed. A couple of wives were there as I recall, but is was mostly a gathering of old men.

I took a seat in the back, intent on watching and learning, but Walter made me introduce myself and tell a little about my background – since even he didn’t know anything about me – and then they got on with the meeting, which was a discussion about an article in The American Bee Journal. And that was it. No coffee, snacks, pretty much a one topic discussion, and done. They stood around in the parking lot afterwards, like every beekeeper’s meeting and eventually drifted away.

I stayed to lock up, and the last person to leave was that guy who looked to be about my age. He introduced himself as Russell, but everybody calls me Buzz he said. A guy named Buzz at a bee meeting – who would have thought. We chatted a bit, found out we lived kind of close to each other in the north part of the county and he invited me over to see his operation when I had time.

New job, just moved, on the road – time got away from me for a bit. I missed a couple of meetings and suddenly it was Summer. I came over. We looked at some of his bees – he had close to 100 I think, with some in his yard – nucs to grow and feed mostly. And his honey house – as nice a piece of work as you can imagine.

We got to know each other a bit more, and he was telling me about those splits in his yard, and I asked about going along on his beeyard run and watching.

“Might even do a story on this”, I said, and he was game. I went, did the story, and we’ve been doin’ stuff ever since. I’ve done several stories on Buzz and his operation over the years. It’s just too easy. He had a truck – a 53 Ford Flatbed when I met him, a 88 Chevy 1 Ton duel wheel now, and used to use a bee blower, has a Maxant vertical flail chain uncapper and a great big Maxant extractor. His extractor is a 30-frame radial with serial number 0017, so he was one of the first Maxant customers. There wasn’t, and I’m guessing still isn’t a beekeeper in Medina county with this size operation. He wasn’t huge when I met him, and he’s downsized over the past 30 years, but he was, and still is, big enough to be interesting.

Buzz had a day job when I first met him. His was a firefighter and Paramedic. That’s one of those jobs with hours, even days of complete boredom, followed by a short burst of extreme, very extreme excitement. Car accidents, other kinds of accidents, sick people, house fires, auto fires – that was his life. But it was those hours of boredom that got him into beekeeping in the first place. A swarm landed near the fire station he was at one day and somebody asked him if he wanted it. How many people do you know got started that way? He got the swarm, got it home, got some equipment and suddenly was a beekeeper. Well, not quite. But his free time at the firehouse let him get caught up assembling equipment and getting started. That was 43 years ago.

Another thing his job did was give him several days off in a row, which made building his house easier, keeping bees easier, and it made becoming a county inspector easy, too. You have to understand how the Ohio Department of Agriculture’s (ODA) Inspection system worked at the time to see how this came about. A county inspector actually worked for the county as a seasonal contract employee. But the inspector answered to and was trained by the ODA Regional or State Inspector. The county advertises the job, then vets the person through the Inspection folks in Columbus, Ohio where the HQ for the ODA is. If that person looks good, they attend training classes held by ODA and learn the ins and outs of inspection, of handling colonies, of dealing with beekeepers, of finding where bees are hidden, of working with beekeepers to get their colonies healthy – of how to be a good inspector.

At the time there were three or four Ohio Regional Inspectors and a State Inspector. Today, there’s only a part time State Inspector remaining. But back then there were a lot more beekeepers to inspect. So for three of the first four years he kept bees, he got to see everything that can go wrong in a beehive, and had to learn pretty much how to fix it.

He got to know most of the Medina County beekeepers, too, and he came to find that back then, lots of people had bees, but didn’t do much with them.

“Lots of folks had bees, back before mites, and you didn’t have to do much to get some honey”, he’s told me several times. But what he did was to offer to help some of these folks – widows who had lost a beekeeping husband, like that – and split the honey those bees made. Pretty soon he was managing over 100 colonies, owning about half of what he was managing.

It was 38 years ago he and Nancy got married. Nancy is a numbers person and at the time was working in the world of taxes and such. What with the added income and financial details from all the honey Buzz was making, it was a good thing somebody was paying attention. Nance still takes care of the business side of the business, dealing with tax issues, income, expenses, forms and the like. A pretty smart lady is Nance.

Nancy says the secret to doing well at any festival is to look good and make an outstanding presentation. Done well, price is seldom an issue.

Pumpkin and apple pollination made their way into the business in the 80s. With a truck and a few strong friends Buzz would load up at night and head out to one of Medina’s more progressive nurseries, that grew and sold pumpkins around Halloween time, and sponsored hayrides all Fall to get kids, and parents into an off-season buying frame of mind.

Apples were a spring time pollination job, and a local, fairly large orchard hired his bees for that. He sold them his honey but they put their own label on the bottles, but they put it on a lot of his bottles. This went on for some time, until one spring the orchard manager picked up some of his bees and moved them in the daytime. All those colonies were lost essentially, so Buzz and the orchard parted company.

Early on Buzz was making a lot of honey and bottling it in his kitchen. At first he made his own extractor by buying the guts for a Root Extractor right here at the company, and getting a galvanized garbage can to hold what he extracted. But after a while his operation grew to the point where on a good year he’d make a really good crop of honey. After not too many years, however, this began to wear thin and something had to change. Sticky floors finally won. They were making way more than the kitchen could handle so they moved their harvest operation out to the garage for a time, and eventually built the barn to handle crops up to 10,000 pounds on a good year. Nancy was making hand lotions, lotion bars, lip balm and candles first in the kitchen and that moved out of the house to the garage also. They were selling all this at several festivals, selling to some grocery stores, doing several seasonal and year round farm markets, and selling to some who used his honey in gift boxes.

Buzz had put up what he calls his barn just a year before we met. It’s a workshop, with his table saws and such in one end, and he parks his tractor in that part of the barn too. In the middle there’s storage for pails, boxes of bottles and the like, plus a desk. At the other end of the building is the garage door he backs his truck up to when unloading supers and drops them off right onto a conveyer belt that slides his supers right over to his uncapper.

Frames are dug out of the supers, dropped into the uncapper then moved onto a large stainless table to be loaded into the extractor. His Maxant uncapper is old enough that it doesn’t have a wax spinner below it, but there is a container that catches the wax and honey that drops down. When on the table they can be scratched with a fork if needed before loading, making everything run smooth. Honey drains off the table in the center and is caught below.

While the frames are spinning, Buzz moves the now-empty supers from the uncapper area to the other side of the extractor and stacks them there until the frames are done. Frames are removed, placed back in the supers and then back on the conveyer and back on the truck. He puts one or two wet supers right back on the hives. They aren’t off the hives more than a day, ever, and often back on the same day.

Honey runs out of the extractor into a sump that separates a lot of the floating wax from the bulk of the honey, which is then pumped up and run through a straining sock and drips into a pail. The sock is pretty coarse, and what he catches are the really big chunks of wax and any bees or other extraneous material that made it this far. His honey is stored in these pails.

Buzz uses a Maxant bottling tank, just barely warming the honey before bottling. If a pail crystalizes (his barn is only heated when he’s working in there, ambient temperature the rest of the time), he’ll put it in one of his warming boxes. These are made from two inch Styrofoam covered with foil that sit on a platform that holds a 50 watt bulb. The insulation and the heat will melt two pails full of honey in about 24 hours without overheating the honey.

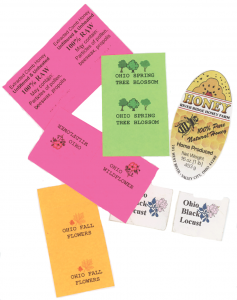

Buzz and Nance run River Ridge Honey Farm, which is the label they sell. But one of the things about Buzz that I’ve always liked is that he listens to folks who have good ideas. Buzz harvests three times a year so he has three crops of seasonal varietal honey. On the top of the early season crop they put a sticker that says ‘Ohio Spring Tree Honey’, on the summer harvest they put ‘Ohio Wild Flower Honey’ and on the last crop they put ‘Ohio Fall Flower Honey’. This immediately tells his customers that it’s Ohio honey and they can identify it when they come back and want some more of one or the other.

Buzz still helps out at the Medina County group. He runs a field day at this house, showing anybody who shows up anything they want to see. I’ve been there a few times helping and it’s an intimate, casual learning experience for our beginners. He also helps at our field days in the beeyard the Medina group has on Root property here, and he’s always in attendance at our pre-meeting beginner’s class each month.

Buzz and Nancy have just this Summer retired from running the Medina County Beekeeper’s Fair Booth, which they did for 24 years. Getting honey sellers organized, wall displays hung, shelves cleaned, everything ordered on time, video displays up and running, the honey show organized, tasting jars organized for every kind of honey that gets sold at the booth by club members, prices sorted out, and then just working the booth mornings and evenings and in between selling honey, candy, lotions and the like for the whole week of our fair. Then after the fair they took it all down, stored it carefully away in the garage attic and did it all again next year. Not too long ago Nancy retired from being the Newsletter Editor, which she did for 18 years And for those of you who have done this, you know the difficulty in getting information from the people who have it to the people who need it. I was one of those for some time when I served as Program Chair and then as President of the group. And she put up with it for all that time.

So – River Ridge Honey Farm. Buzz and Nancy Riopelle. Good folks who make beekeepers and beekeeping look good.