This content is restricted to Digital and Bundle subscribers only!

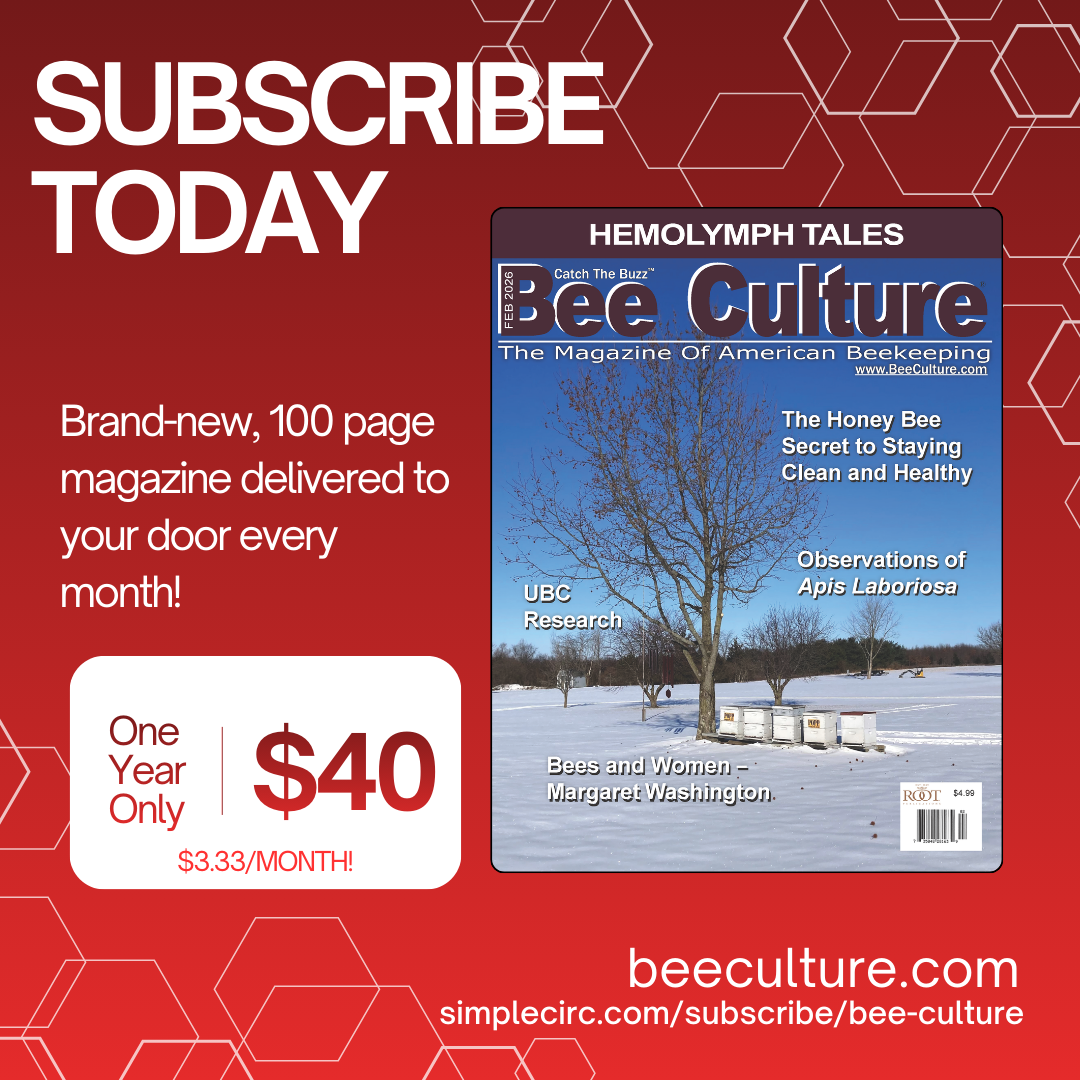

Want to view it? Subscribe here: https://simplecirc.com/subscribe/bee-culture

Log in instructions for first time Digital and Bundle users:

1. The email/username for your account will be the same email you put into your subscription account.

3. Click the “Lost your password?” button and follow the instructions to get the password reset email.

4. Follow the instructions in the email to reset your password. Please check your spam folder if you do not see the email in your inbox!

5. Once your password has been successfully set, you can log in! We do recommend that you check the “Remember me” box to avoid having to log in every time.