Peter Sieling

In the early twentieth century, J.E. Crane wrote a series of articles in Gleanings in Bee Culture on his experiences as an American foulbrood inspector. While visiting A.W. Darby’s apiary in Alburgh, Vermont, he saw a device for clearing bees out of honey supers that was simpler and less expensive than the Porter bee escape1. It works on a similar principle to escape boards except that the bees exit to the outside of the hive and then find their way down to the entrance. According to Crane, “It makes the best kind of escape… We have tested it and it works perfectly.”

Darby’s bee escape was soon forgotten, but it looked so simple, I made several. They worked for me as well as an escape board, plus you can watch the bees exiting the supers.

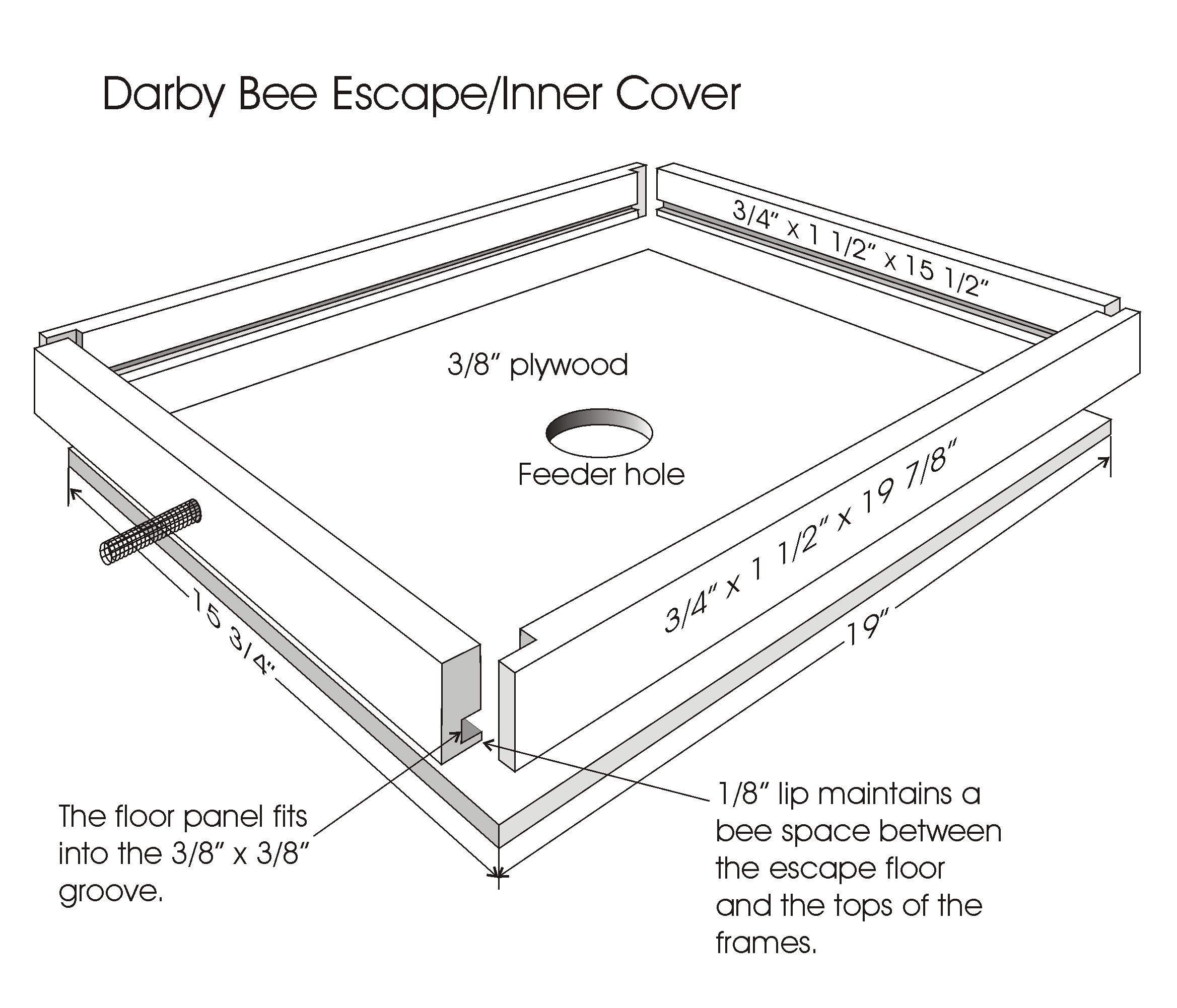

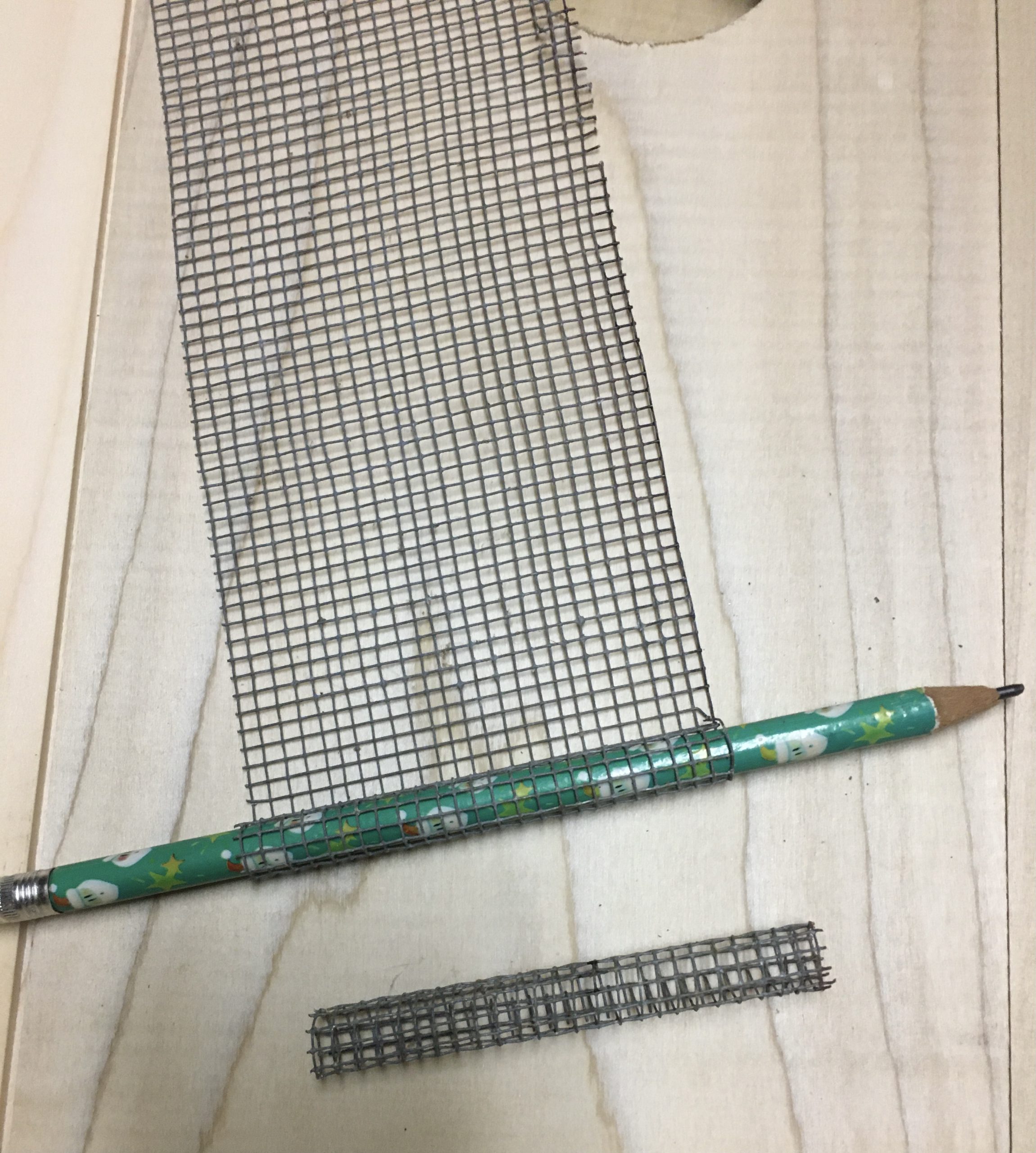

A.W. Darby used his bee escapes as an inner cover, leaving them on the hives year-round. They had a floor with a feeder hole. A quilt provided insulation both Summer and Winter. The bees exited the supers through a three inch long by ⅜” diameter hardware cloth tube. The escape hole without the hardware cloth tube provided ventilation and an upper exit.

I made several escapes to use in place of inner covers. I used ¾”-thick poplar for the rails. The panel could be ¼ or ⅜”-thick plywood. I used ⅜” tongue and groove poplar because I could make it faster than driving to the building supply center. Kiln dried lumber will expand in width so the panel needs space to expand in the groove. Using ¼” or ⅜” plywood would be easier because it is dimensionally stable. I made the rails 1½” in height to make space for one inch foam insulation above the panel and ⅛” lip underneath to keep the bee space between the top bars of the frames and the escape board.

To use the escape, remove the honey supers. Cover the feeder hole with anything that works—for example, a jar lid or a wood block. After an hour or two, you will see a steady parade of bees exiting through the tube. As with other bee escapes, the supers need to be bee proof to prevent robbing. Robbers try to enter at the base of the tube rather than the end. In 24 to 48, hours the supers will be almost empty of bees.

An even simpler Bee Escape

The easiest, fastest and cheapest version of the bee escape uses an inner cover, a hive shim and the hardware cloth tube. The hive shim is available in bee supply catalogs, but they are easy to make. It’s a frame, about 1”-wide with the same outside dimensions as a bee hive—19⅞” x 16¼” for a ten frame hive. Drill a hole in the front to fit the tube. After removing the honey supers, put the inner cover back. Cover the feeder hole, add the hive shim with the tube facing to the front and add the supers and the cover.

Conclusion

After the Fall harvest I stacked the wet supers above inner covers so the bees could clean them out. The bees wouldn’t abandon the empty supers even on cold mornings. I made half a dozen escape boards and put them under the supers in the mid-afternoon. An hour later you could watch the bees leaving. By 9:00 am the next morning approximately 90% of the bees had exited… After taking off the supers, I removed the tube, inverted the bee escapes, put a one inch insulation board on top and replaced the telescoping cover.

Like the Porter escape, the Darby escape can clog. The advantage over Porter escapes is you can see the clog without removing the supers. The Darby escape board works best when the weather is warm.

About the author

Peter Sieling is a wood technologist and beekeeper in Bath, NY.