By: Jim Berndt

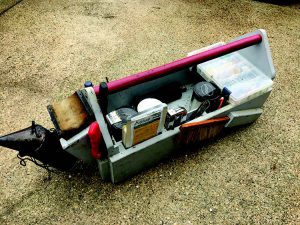

I am not a naturally tidy person; I am not one of those people who knows precisely where everything is and have my tools outlined on a pegboard in my shop. Having said that, I like to have the tools at hand when I am working on a project. Many beekeeping operations can be done with nothing more than a hive tool and a smoker but others require a variety of tools and supplies. I wanted some way to keep all of these things together and handy as I moved from hive to hive and apiary to apiary. I decided that a simple toolbox, dedicated to beekeeping, would be the best solution. That way when it’s time to check my bees all I have to do is grab my toolbox and go (Figure 1).

I’ve seen other beekeepers use a variety containers to carry materials around the apiary – five-gallon buckets, modified nuc boxes, and a variety of other small containers. One of the problems I noticed with many of these repurposed containers is that most of the stuff sits in a big pile in the bottom, requiring the beekeeper to dig through the pile to find the thing they need. I wanted something a bit more organized – something that would hold the tools I use all of the time in dedicated slots but still have some open space to hold the miscellaneous things I need on any given day. I also wanted a way to keep track of some of the bits and pieces that are too small for a dedicated slot but could be hard to find in the bottom of the box – things like extra screws and nails, an extra lighter, or empty queen cages. And I wanted to be able to carry my lit smoker in or on my toolbox. This would allow me to carry all of my tools in one hand as I move from hive to hive and would leave the other hand free to carry other things.

Figure 1. My beekeeping toolbox (now a couple of years old) with the tools and supplies I use most often.

Figure 2. Inside end of toolbox showing slots for hive tool and knife as well as dedicated holes to keep various screwdrivers.

Figure 3. Slots along the inside side wall of the box are sized to hold my notebook and stapler; a block at the end of the slots is drilled to hold markers and pens.

So, what types of things do I need or want to carry when working my bees? Beekeepers love gadgets and it would be easy to overload a box with every conceivable device for every possible need. I designed my toolbox around the things I use frequently, leaving space to carry specialty items when they are needed. So what do I want to have available all of the time? I want to have a couple of hive tools and a smoker. I need fuel for my smoker and a lighter to get it started. I occasionally use a bee brush and a frame hanger, so I want those handy. I also need the tools to make simple repairs to my hives if I find a problem. If I come across an unmarked queen I want my queen marking pens and possibly an empty queen cage. I need to have my notebook, pens and markers to maintain my records and for making notes on frames as needed. I also need the space to carry the things related to what I am doing on that visit; wash bottles for mite counts, sugar for feeding, a couple of extra frames, or possibly packages of mite treatments. This toolbox works well for me, I can easily find all of these things without having to dig through a pail or sort through an unorganized box.

Like many projects, my “simple toolbox” became a little more elaborate by the time I incorporated all of the features I wanted; still, I have been pleased with the results. My beekeeping toolbox is a version of the classic tradesman’s wooden toolbox – simple to build and easy to adapt to specific needs. On one end I keep most of my tools in dedicated slots. Since I keep both top-bar and Langstroth hives, I carry a traditional hive tool and a serrated knife (my top-bar hive tool). My hives and other beekeeping equipment are assembled with a variety of screws so I keep screwdrivers for each type handy (Figure 2). Along one of the side walls I have slots for my stapler and my beekeeping notebook. Next to those slots, I have a strip of wood drilled out to hold markers and pens (Figure 3). My bee brush fits in a slot on an outside wall, angled upward so that the brush doesn’t fall out when moving the box (Figure 4). On the opposite long side I have cut slots to fit my frame hanger brackets so the brackets slide in along the box bottom and the rails are snug against the box side. A small toggle keeps the frame hanger in place (Figures 5 and 6). One end of the toolbox has a wooden bracket to hold my smoker and a wooden block drilled out to hold my lighter (Figure 7). A hole drilled through the end is sized to hold my smoker cork so it doesn’t get lost when the smoker is in use.

Figure 4. The holder for the bee brush is sized to fit the brush handle and angled upward to keep the brush from falling out.

Figure 5. Slots cut through the tool box side allow the frame hanger to rest flat against the side of the box.

Figure 6. I attached feet at either end of the box to provide clearance for the flange of the frame hanger, which extends slightly below the bottom of the tool box.

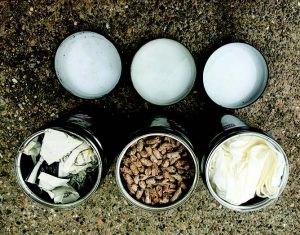

The interior of the box is open and used to carry whatever I may be taking out to the beeyard on that day. I usually carry three coffee cans with tight fitting lids, one each filled with tinder and hardwood pellets for my smoker, and one filled with thin gloves to wear during inspections (Figure 8). My box is long enough to hold a standard Langstroth frame and deep enough that a deep frame can rest against the handle and not fall out.

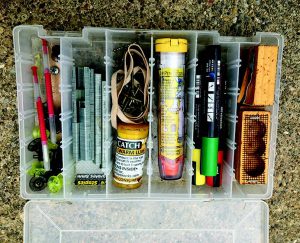

My solution for organizing the small bits and pieces is a plastic tackle box. I have attached wooden rails to the bottom of the tackle box, which fit against the inside walls of the tool box, so the box can sit snugly on top of the toolbox (Figure 9). This keeps the tackle box easy to access and keeps it from taking up space in the interior of the toolbox. My tackle box usually contains things like extra screws, nails, an extra lighter, queen cages, queen paint markers, and other small items (Figure 10).

I used ¾” (nominal 1”) pine lumber to build my box, which was what I had on hand. All of the joints are glued and screwed together for strength. The handle has one large bolt on each end for strength and a smaller screw on each end to keep the handle from rotating. The interior partitions are made from ¼” plywood.

The holder for the smoker on the end of the box was the only tricky part of the construction. The smoker is held by the bellows so the wooden bracket needs to be sized for the bellows of your smoker. I laid my smoker on its side and traced the profile of the bellows when it was fully expanded – I then transferred that profile to my lumber to make the sides of the bracket to hold the smoker. I drilled a hole in the plate on the front of the smoker bracket that matches up with the hole in the bellows which blows air into the smoker. This allows me to pump the smoker occasionally to keep it burning while leaving it in its holder on the toolbox (Figure 11).

Figure 7. Wooden bracket at the end of the box holds my smoker and a block with an appropriately-sized hole holds my lighter.

Figure 8. Sealed cans in my toolbox keep smoker tinder and fuel dry while another can keeps thin exam gloves clean and ready to use.

Figure 9. Wooden rails attached to the bottom of the tackle box (screwed from the inside of the box) are spaced so that they fit snugly inside of the sides of the tool box.

If I were to build another toolbox I would consider doing a few things differently. First, I would probably build it out of some thinner lumber. The ¾” pine of my box is very strong – probably much stronger (and heavier) than needed. Using thinner stock would cut down on the weight of the empty box. Second, I would probably make it a bit shorter as the current length is a bit awkward to maneuver sometimes. I think the ideal length might be such that a standard frame could just fit in the interior space (about 3-4” shorter than my box is now). I might make the sides of the box an inch or two deeper to give a little bit more storage space.

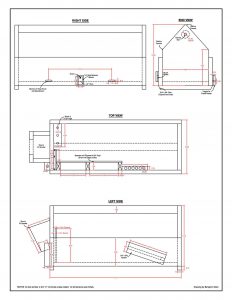

The drawing shows the dimensions of my toolbox. I provided these dimensions for reference only as one of the great advantages of this design is that it is adaptable to the size the user needs. Give some thought to what you want to carry and size your box accordingly. I used simple butt joints for my toolbox, but if you want to make a stronger (or more impressive) joint you could use a box joint or dovetails. In the same way, I used inexpensive pine lumber and painted the finished box, you could use some nice hardwood and stain your box if you prefer something a bit showier.

Figure 10. Inside of my tackle box that sits on top of my tool box. These little bits and pieces would otherwise become lost in the bottom of my toolbox.

Figure 11. Smoker bracket with smoker. Note that the side gusset of the bracket is the same size as the side of the smoker bellows. Also note the hole drilled in the face of the bracket (red arrow) – this hole matches up to the air hole on the smoker and bellows and allows the smoker to be pumped while sitting in the bracket. The hole in the end of the toolbox (yellow arrow) holds the smoker cork when not in use.